Printed Circuit Board Fabrication Service for Automotive PCB Applications

In today’s auto industry, Printed Circuit Board Fabrication plays a key role. Cars now have smart systems, sensors, and advanced electronics. This makes reliable fabrication vital. You need boards that resist heat, vibration, and moisture.

Let’s explore how top-tier Printed Circuit Board Fabrication service supports automotive needs.

Why It Matters in Automotive

Automotive electronics manage safety, comfort, and efficiency. Think ABS, airbags, infotainment, and EV systems. These systems rely on durable PCBs. A small defect can cause big issues. Safety depends on strong board designs and fabrication.

Printed Circuit Board Fabrication in this sector requires tight controls:

- Precise trace width and spacing

- High-quality materials for thermal stability

- Vibration-resistant board structures

Next, OEMs also need traceable records. This ensures each board meets automotive standards.

Key Fabrication Requirements

Auto PCB applications demand specific manufacturing steps. Each step lowers risk and boosts performance.

1. Material Selection

Choose materials like FR‑4, polyimide, or ceramic. These resist high heat. For EV batteries and sensors, thermal endurance matters most. A robust Printed Circuit Board Fabrication service checks every sheet and laminate.

2. Controlled Processes

Boards go through drilling, plating, and etching. Each step must maintain tight tolerances. Even a small plating error can cause open circuits in safety modules.

Next, alignment and copper thickness are inspected. Automated systems help ensure consistency and reduce defects.

3. Thermal Stress Testing

Automotive PCBs face heat from engines and electronics. A fabrication service tests boards under thermal cycling. These tests mimic real-world conditions to confirm reliability.

4. Vibration and Shock Testing

Road bumps and engine movement stress boards. Vibration tests help catch delamination or cracks early. A strong Printed Circuit Board Fabrication service uses testing rigs to simulate these conditions.

Quality Assurance & Certification

Automotive requirements exceed consumer electronics. Manufacturers must follow:

- IATF 16949: Strict automotive quality standard

- IPC-A-610 Class 3: Highest reliability level for PCBs

A certified Printed Circuit Board Fabrication service logs every step from material batch to final inspection. This traceability builds trust and ensures compliance.

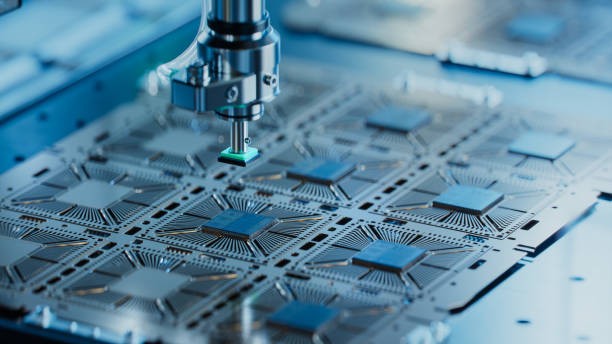

Advanced Fabrication Technologies

Today’s fabrication uses cutting-edge tools and methods.

- Fine line etching for high‑density boards

- Controlled impedance routing for high-speed data

- Microvias and HDI layers for compact designs

These technologies support ADAS, infotainment, and ECU systems with reliable signal flow and tight form factors.

Integrating with Assembly

Boards aren’t just fabricated; they’re mounted with parts. A good Printed Circuit Board Fabrication service works closely with SMT and BGA assembly teams. Why? It saves time and avoids errors. A seamless handoff ensures solder pads, vias, and thermal profiles match assembly needs.

Design for Manufacturability (DFM)

Automotive PCB design should be fabrication-friendly from the start. A top service offers DFM reviews. These include checks on:

- Minimum trace width verification

- Via-in-pad vs. dogbone layout checks

- Panelization strategy and fiducial alignment

These checks reduce rework and speed up production. They also improve yield and lower costs in high-volume runs.

Testing and Inspection

Automotive boards go through the following steps:

- Automated Optical Inspection (AOI): For surface issues

- X-ray Inspection: For internal defects like voids

- Electrical Test: Bed-of-nails or flying probe to verify circuits

This multi-step testing ensures boards are ready for rugged automotive use.

Traceability and Documentation

Every board gets a unique ID. This helps track production batches. Traceability matters for recalls or performance analysis. A reliable Printed Circuit Board Fabrication service also provides full documentation—material certificates, process logs, and test reports. OEMs rely on these to meet compliance and audit requirements.

Benefits of Specialized Automotive Fabrication

Using a dedicated service yields clear advantages:

- Improved Reliability: Fewer field failures

- Compliance-Ready: Meets OEM and safety standards

- Faster Time-to-Market: DFM and testing speed up production

- Cost Control: Higher yields and fewer defects

These benefits drive value for automotive OEMs and tier-1 suppliers.

Final Takeaway

Automotive electronics demand top-tier PCB solutions. From material choice to testing, every step matters. A high-quality Printed Circuit Board Fabrication service ensures boards work reliably under heat, vibration, and shock.

Partnering with a trusted provider gives you peace of mind. You get durable boards, strong documentation, and engineering support. This focus on quality makes all the difference for complex automotive systems.

In conclusion, using a specialized approach to Printed Circuit Board Fabrication can elevate your automotive projects. Choose a provider that handles precision fabrication, tight process control, and thorough testing.

At American Progressive Circuits, Inc., we deliver end-to-end automotive PCB solutions backed by certified processes, expert engineering, and a proven commitment to quality. From prototyping to volume production, we help you build reliable boards that perform in the most demanding environments. For more, contact us today.

FAQs

1. What makes automotive PCB fabrication different from standard PCB fabrication?

Automotive PCBs must withstand extreme temperatures, vibrations, and humidity. This requires tighter tolerances, more robust materials, and thorough testing compared to consumer-grade boards.

2. Why is material selection so important in automotive PCB applications?

Materials like polyimide and ceramic are chosen for their high thermal stability. These materials ensure the board doesn't degrade under the heat and stress common in automotive environments.

3. What certifications should a Printed Circuit Board Fabrication service have for automotive use?

Key certifications include IATF 16949 for automotive quality and IPC-A-610 Class 3 for high-reliability PCBs. These ensure the boards meet strict industry standards for safety and performance.

4. How does Design for Manufacturability (DFM) help in automotive PCB production?

DFM reviews optimize board layouts for easy, error-free fabrication. This minimizes rework, reduces cost, and ensures high production yields, especially in large-scale automotive runs.

5. What types of testing are essential for automotive PCBs?

Critical tests include thermal stress testing, vibration and shock testing, X-ray inspections, and automated electrical tests. These tests confirm the board's durability and performance before deployment in vehicles

For more about products, visit our page.